기본 정보

모형: 2017First GradeSi98

Additional Info

포장: bag

생산력: >10000ton

수송: Ocean,Land

원산지: Ningxia China

지원에 대한 지원: >100000ton

인증 : standard

포트: Port of Shanghai,Port of Shenzhen,Port of Tianjin

지불 유형: L/C,T/T

인 코텀: FOB,CFR,CIF

제품 설명

Silicon Carbide (SiC)

General description: The molecular formula of silicon carbide is SIC, it is generated by SiO2 and petro coke or anthracite through reduction reaction under the condition of high temperature, there are two kinds of it: black SIC and green SIC. Green SIC is produced by putting NaCl into the raw material during the processing period whose properties are better than the black SIC of the same grade.

Properties: Physical properties of SIC is extreme hardness, high temperature-resisting ,chemical erosion resisting, radiation resisting and good electric conductivity and thermal conductivity, low thermal expansion, it`s Moh`s hardness is 9-9.5.

Usage: It is widely used in the fields of abrasive, grinding, heat resistance, electronics, aviation, metallurgy and ceramics and so on.

- Used as abrasive materials

- Used as deoxidizer and high-temperature resistant material

- High purity material can be used in producing semi-conductor.Sic fabrics.

Silicon Carbide Lumps

Size: 0-10MM/1-10MM/1-5MM/0-25MM/0-100MM or as per buyer`s requirement.

packing:1mt plastic woven bags or as per buyers` requirement.

Processing method:Crushing and so on.

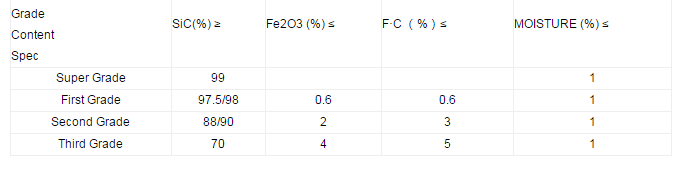

Specification:

Due to its stable chemical properties, high thermal conductivity, small coefficient of thermal expansion and good wear resistance, silicon carbide has many other applications besides abrasive materials. For example, silicon carbide powder can be coated on the turbine wheel or the cylinder block in a special process The inner wall can improve its wear resistance and extend the service life of 1 to 2 times; to be made of advanced refractories, heat shock, small size, light weight and high strength, energy-saving effect.

Low-grade silicon carbide (about 85% SiC) is an excellent deoxidizer that accelerates the rate of steelmaking and facilitates the control of chemical composition and the quality of the steel. In addition, silicon carbide is also used extensively in the production of silicon carbide rods for electric heating elements.

Pure silicon carbide is a colorless and transparent crystal. Industrial silicon carbide due to the impurities contained in different types and content, but pale yellow, green, blue and even black, with its purity varies with purity. [3] Silicon carbide crystal structure is divided into hexagonal or rhombohedral α-SiC and cubic β-SiC (called cubic silicon carbide).

α-SiC forms many different variants due to the different stacking sequences of carbon and silicon atoms in its crystal structure, and more than 70 species have been found. β-SiC at 2100 ℃ above into α-SiC. Industrial production of silicon carbide is the use of high-quality quartz sand and petroleum coke in the resistance furnace refining. The refining of the pieces of silicon carbide, crushing, acid wash, magnetic separation and screening or water made of various particle size products.